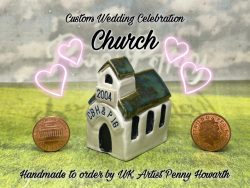

Penny Howarth is well known for her “Penny Pottery miniature ceramic house” range, various differently shaped collectable village buildings and accessories, differing in rarity from houses, barns, sheds and lighthouses, to boats, trees and even UFOs .

Penny also creates personalized village buildings that sit perfectly in the collectable range. The following buildings can be customized and are specially handmade to order, but if you have something different in mind, you can always contact Penny to discuss.

The Creation Process

Step 1: Penny starts by creating the item from stoneware clay in her garden studio.

Step 2: The items are dried for around 3 to 5 days depending on the size, they need to be bone dry before they can be fired.

Step 3: The dry stoneware clay model is now extremely brittle and has to be carefully loaded into the kiln and fired to around ~980 C (1796 F) for around 10 hours and cooled for a similar time.

Step 4: The item is now “biscuit” or bisqueware. Slightly less brittle but able to be more easily handled. The clay at this stage is still absorbent so is ready to be glazed.

Step 5: The item is glazed with 5 coats for each colour. Glaze is a liquid or powdered mixture of materials which creates a glassy coating once fired. Occasionally underglazes are used, these are typically matt and can be glazed over with clear glazes.

Step 6: The glazed pieces are “high” fired to 1250C (2300F) for approx 12 hours and cooled for a similar time.

Step 7: Items are inspected, wrapped and sent worldwide.

Why does it take 2.5 weeks to create a custom item? Kilns need to be filled before a bisque or glaze firing can be run. This careful scheduling means that 2.5 weeks is the average time.

Leave Nothing Behind but Beautiful things

Penny’s philosophy is to leave the world in a better place than when she entered it. Penny Pottery is run in a sustainable way some examples being:

- Upcycled and/or Recyclable packaging

- Compostable bubblewrap

- Solar & Wind Electrical Energy used for Kiln firings.